Grinding technology based on a needle process

Precision grinding technology is used to produce needles and grinded pins for a contact probe and a ionizer, a HID lamp electrode.

Grinded Pins

Shape

Several types of grinded shapes are available as below. Both ends can be grinded.

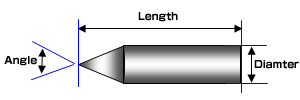

Cone Shape |

Flat Shape |

Ball Point Shape |

Round Shape |

Available Size

|

|

Grinding

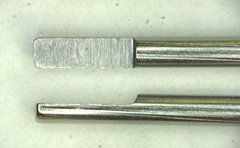

1.D-cut

|

2.H-cut

|

Combined Processing

Grinding +D-cut

|

Integration of Microfabrication Techinologies We provide combined processing by applying both grinding and machining technologies. Rod material is firstly processed by CNC machining, then follows with D-cut/ H-cut and tip grinding. Based on your specifications, we can also assemble the machined rod with coil by laser or resistance welding. Please consult us for further details. |

Material

We are specialized in precision refractory metal grinding of materials such as tungsten, stainless steel, etc.

Material:Tungsten Diameter:2.0mm Length:20.0mm |

Material:Brass Diameter:1.0mm Length:15.0mm |

Material:SUS304 Diameter:0.5mm Length:20.0mm |

Material:Molybdenum Diameter:0.7mm Length:15.0mm |

|

[Head Office / Main Plant] |